Product Brief

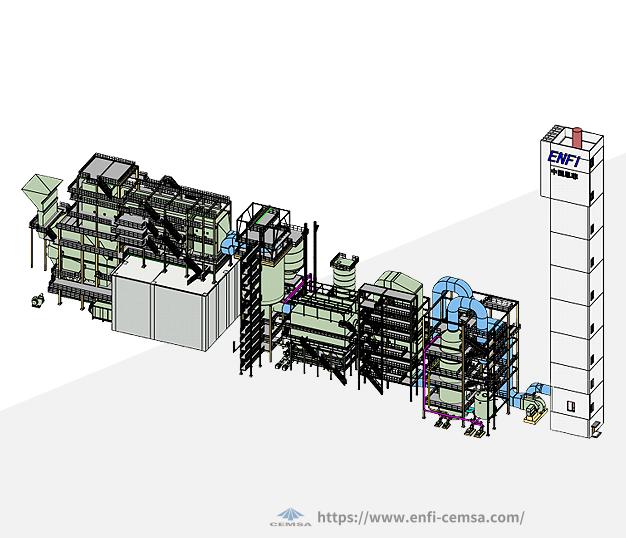

An ultra-low-pollutants off-gas emission system

The ultra-low emission technology and equipment independently developed by ENFI for collaborative purification of off-gas pollutants, combined with integrated wet absorption technology, can realize ultra-low emission of multiple pollutants, suitable for the cleaning of complex off-gas from organic solid waste incineration

Specification & Series:Customized process equipment sizing can be carried out according to waste incineration capacity, off-gas properties, streams properties and procedures, transport conditions, client requirements and emission standard,etc.

Specification & Series:Customized process equipment sizing can be carried out according to waste incineration capacity, off-gas properties, streams properties and procedures, transport conditions, client requirements and emission standard,etc.

Processing Capacity:SO2≤10mg/Nm³

NOX≤100mg/Nm³

HCl≤10mg/Nm³

off-gas dust≤10mg/Nm³

Processing Capacity:SO2≤10mg/Nm³

NOX≤100mg/Nm³

HCl≤10mg/Nm³

off-gas dust≤10mg/Nm³

Application Fields:Solid waste treatment/recovery and off gas treatment

Application Fields:Solid waste treatment/recovery and off gas treatment

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

Low system cost, high controllability, high equipment quality, long service life and high adaptability to continuous update of technology.

Low system cost, high controllability, high equipment quality, long service life and high adaptability to continuous update of technology.

Process flow can be customized according to different off-gas properties and emission standards: Chinese national standard, EU standard and ultra low emission respectively.

Process flow can be customized according to different off-gas properties and emission standards: Chinese national standard, EU standard and ultra low emission respectively.

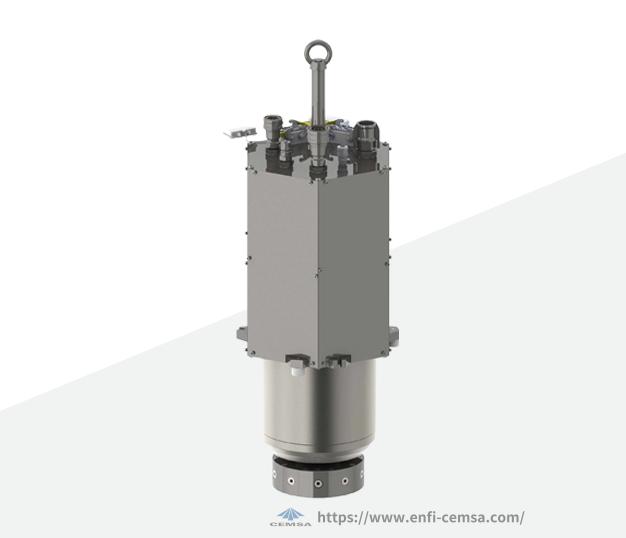

The made-in-China atomizer is independently designed and produced by ENFI. Stable and reliable, it easy to operate and maintain, with favorable pricing, short installation time and timely after-sales maintenance.

The made-in-China atomizer is independently designed and produced by ENFI. Stable and reliable, it easy to operate and maintain, with favorable pricing, short installation time and timely after-sales maintenance.

Low-temperature treatment of dioxin in fly ash. The decomposition efficiency of dioxin is 95% under 300-350℃.

Low-temperature treatment of dioxin in fly ash. The decomposition efficiency of dioxin is 95% under 300-350℃.

Working Principle

The off-gas treatment process flow is “SNCR+semi-dry process for acid removal+activated carbon injection+dry powder injection+bag filter+wet process for acid removal+SCR”

The Application Achievements

Related Recommendations