Product Brief

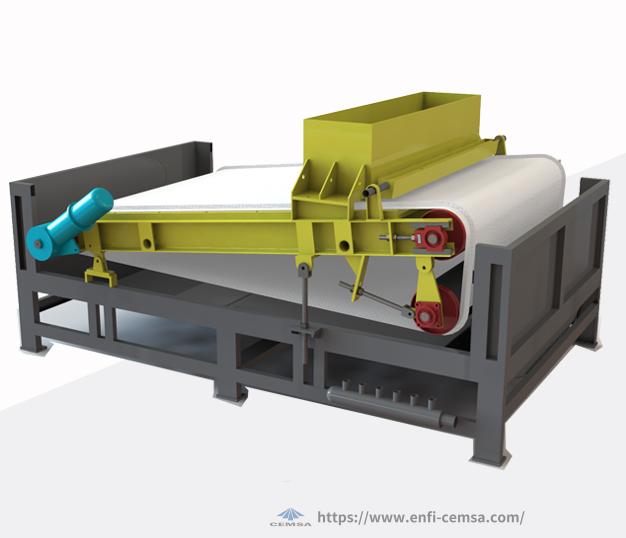

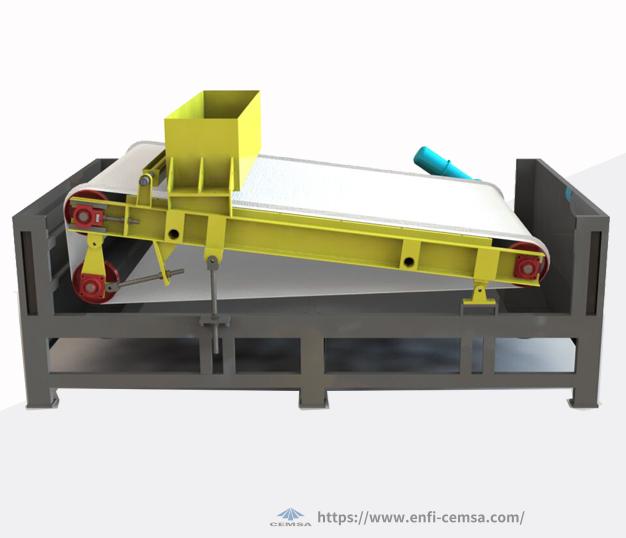

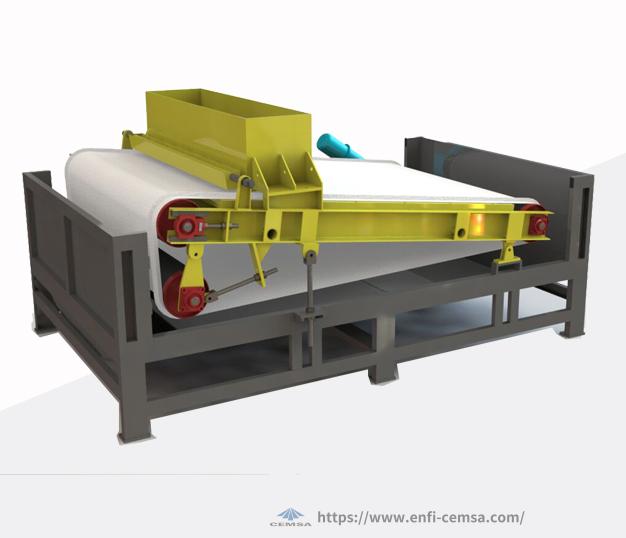

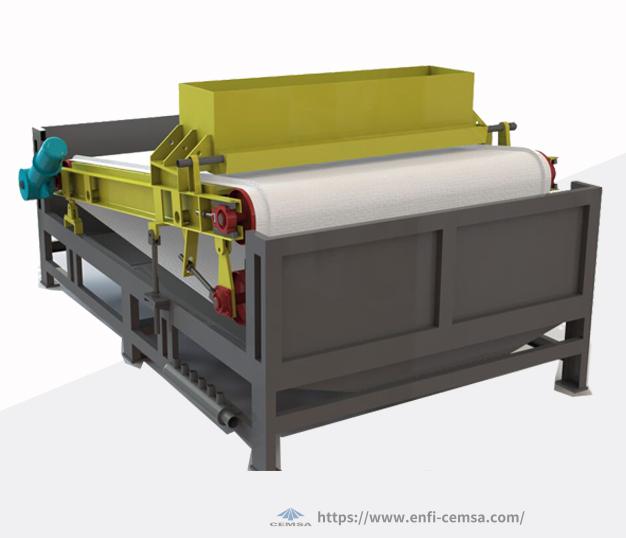

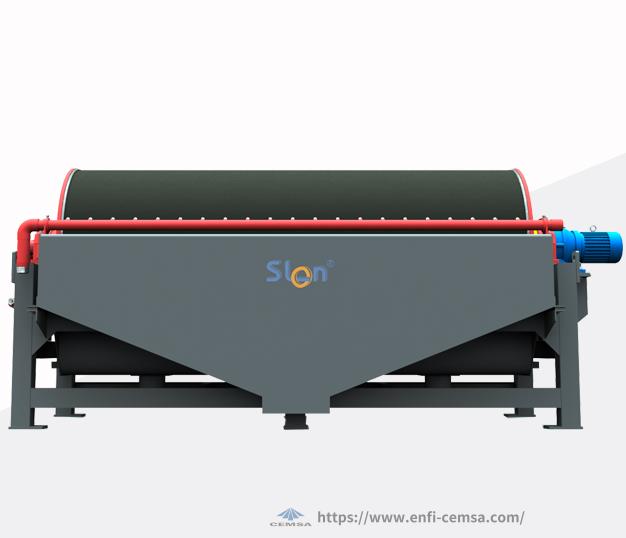

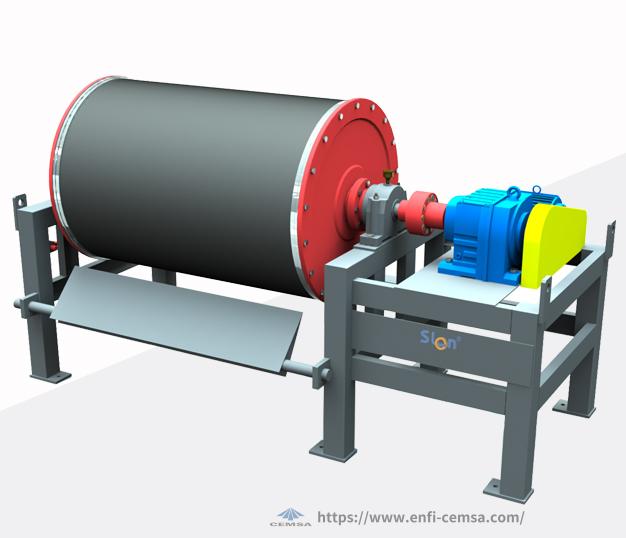

Belt Type Magnetic Separator

The belt type magnetic separator is suitable for iron removal and purification of non-metallic minerals such as quartz sand, potash feldspar, nepheline and kaolin, and also for magnetic product separation and recovery of metallic minerals such as hematite, limonite, manganese ore, wolfram, tantalum and niobium.

Specification & Series:SPBC-0315, SPBC-0820, SPBC-1020, SPBC-1220, SPBC-1525, SPBC-2025, SPBC-2030, SPBC-2525 and SPBC-2530.

Specification & Series:SPBC-0315, SPBC-0820, SPBC-1020, SPBC-1220, SPBC-1525, SPBC-2025, SPBC-2030, SPBC-2525 and SPBC-2530.

Processing Capacity:1~40t/h

Processing Capacity:1~40t/h

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

High intensity: The magnetic system is made of high-performance rare earth Neodymium iron boron material and is not easy to demagnetization;

High intensity: The magnetic system is made of high-performance rare earth Neodymium iron boron material and is not easy to demagnetization;

Large effective separation area: the maximum width and length of the magnetic separation surface can reach 2.5m and 3.0m respectively;

Large effective separation area: the maximum width and length of the magnetic separation surface can reach 2.5m and 3.0m respectively;

Smooth surface of magnetic plate: The magnetic block and the magnetic plate are fixed in a unique way, which is firmly fixed and the whole surface of the magnetic plate is smooth;

Smooth surface of magnetic plate: The magnetic block and the magnetic plate are fixed in a unique way, which is firmly fixed and the whole surface of the magnetic plate is smooth;

Uniform distribution: Two-stage buffering is adopted to distribute the material evenly, and the mesh is distributed evenly, so as to realize the uniform contact of the material in the direction of separation width;

Uniform distribution: Two-stage buffering is adopted to distribute the material evenly, and the mesh is distributed evenly, so as to realize the uniform contact of the material in the direction of separation width;

Clean iron unloading: multi-stage and multi-angle strong washing system is adopted to realize the complete separation of magnetic products and separation belts;

Clean iron unloading: multi-stage and multi-angle strong washing system is adopted to realize the complete separation of magnetic products and separation belts;

Water and energy saving: intensive water supply pipeline is adopted to save water;A single device is driven by only one motor, which consumes less power.

Water and energy saving: intensive water supply pipeline is adopted to save water;A single device is driven by only one motor, which consumes less power.

Working Principle

The slurry enters the feeding box and flows out evenly on the belt with a thin layer through the bottom holes. The magnetic particles in the slurry are captured by the magnetic force of the magnetic system under the belt and adsorbed on the upper surface of the belt.Then the magnetic particles are intercepted by the raised rubber strip on the belt and moves upward with the belt.When it arrived the rinsing zone, the non-magnetic particles will be rinsed out from the magnetic particles.

Technical Parameters

| Type | Bandwidth/mm | Length/mm | Magnetic filed strength(T) | Feed Density(%) | Water pressure(Mpa) | Feed size(mm) | Capacity(t/h) | Motor Power(kw) |

|---|---|---|---|---|---|---|---|---|

| SPBC-0315(Lab) | 300 | 1500 | 1.5 | 10-35 | >0.2 | <3 | 1-2 | 0.75 |

| SPBC-0820 | 800 | 2000 | 1.5 | 10-35 | >0.2 | <3 | 8-10 | 1.5 |

| SPBC-1020 | 1000 | 2000 | 1.5 | 10-35 | >0.2 | <3 | 10-15 | 2.2 |

| SPBC-1220 | 1200 | 2000 | 1.5 | 10-35 | >0.2 | <3 | 15-20 | 2.2 |

| SPBC-1525 | 1500 | 2500 | 1.5 | 10-35 | >0.2 | <3 | 20-25 | 3 |

| SPBC-2025 | 2000 | 2500 | 1.5 | 10-35 | >0.2 | <3 | 25-30 | 3 |

| SPBC-2030 | 2000 | 3000 | 1.5 | 10-35 | >0.2 | <3 | 25-30 | 3 |

| SPBC-2525 | 2500 | 2500 | 1.5 | 10-35 | >0.2 | <3 | 35-40 | 4 |

| SPBC-2530 | 2500 | 3000 | 1.5 | 10-35 | >0.2 | <3 | 35-40 | 4 |

Related Recommendations