Product Brief

Check valve

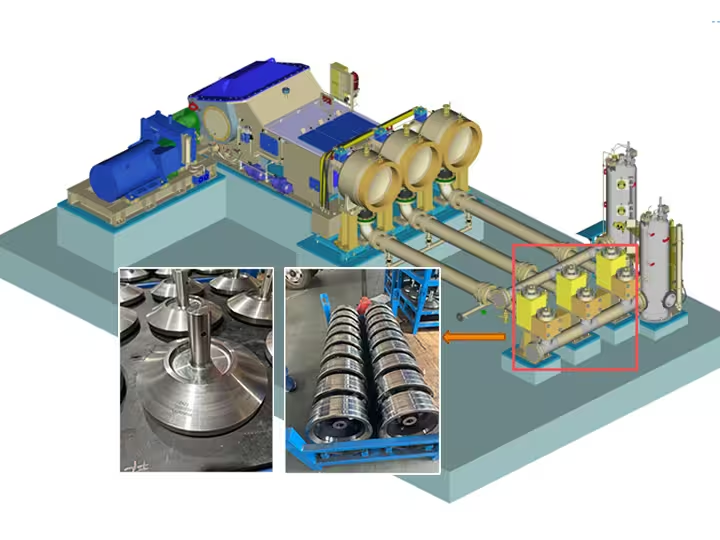

The check valve is a critical component of the feed diaphragm pump in the autoclave of the pressure leaching system, ensuring unidirectional flow. This equipment series significantly enhances erosion resistance and fatigue strength by improving sealing pair structures, optimizing guide rod assembly design, and using specialty materials.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

1. Optimize the sealing pair structure of the check valve to minimize impact forces during closure.

1. Optimize the sealing pair structure of the check valve to minimize impact forces during closure.

2. Adjust the sealing face angle, width and hardness of the check valve to enhance erosion resistance and fatigue resistance.

2. Adjust the sealing face angle, width and hardness of the check valve to enhance erosion resistance and fatigue resistance.

3. Refine the guide rod design and manufacturing of the check valve to prevent disengagement and fracture occurrences.

3. Refine the guide rod design and manufacturing of the check valve to prevent disengagement and fracture occurrences.

4. Select appropriate check valve construction materials and manufacturing processes by fully considering operational demands for cavitation, corrosion, and erosion resistance.

4. Select appropriate check valve construction materials and manufacturing processes by fully considering operational demands for cavitation, corrosion, and erosion resistance.

5. Process materials and operational stability (e.g., slurry particles; preheater pressure/level; slurry concentration).

5. Process materials and operational stability (e.g., slurry particles; preheater pressure/level; slurry concentration).

Working Principle

1. High-temperature diaphragm pump comprises key components including motor, speed reducer, crankshaft, piston, diaphragm, cooling section, buffer tank and valve chambers.

2. The pump operates by converting mechanical energy into hydraulic pressure energy: the motor drives the piston via a gear reducer connected to the large crankshaft gear for secondary reduction, with the resulting liquid pressure deforming the diaphragm to enable slurry intake and discharge.

3. The pump employs a single-acting triple-cylinder configuration, where slurry in contact with the diaphragm corresponding to each piston requires a cooling mechanism to reduce slurry temperature from 220°C to below 100°C. Driven by diaphragm actuation, this drives the opening/closing of remotely positioned inlet/outlet check valves to ensure unidirectional slurry flow, achieving slurry conveyance under high-temperature condition.

2. The pump operates by converting mechanical energy into hydraulic pressure energy: the motor drives the piston via a gear reducer connected to the large crankshaft gear for secondary reduction, with the resulting liquid pressure deforming the diaphragm to enable slurry intake and discharge.

3. The pump employs a single-acting triple-cylinder configuration, where slurry in contact with the diaphragm corresponding to each piston requires a cooling mechanism to reduce slurry temperature from 220°C to below 100°C. Driven by diaphragm actuation, this drives the opening/closing of remotely positioned inlet/outlet check valves to ensure unidirectional slurry flow, achieving slurry conveyance under high-temperature condition.