Product Brief

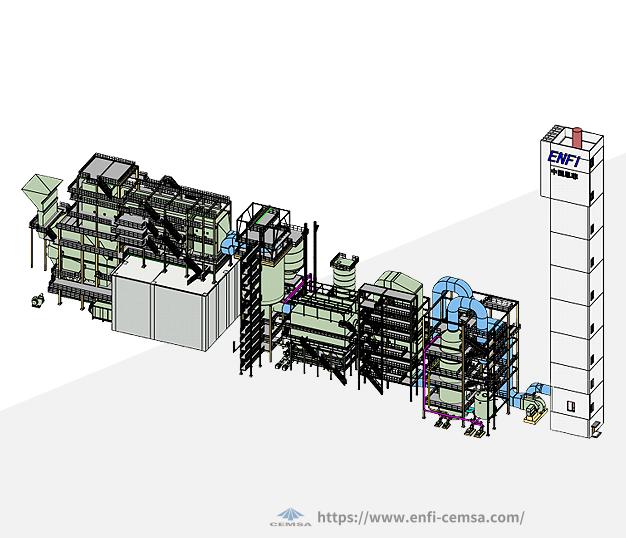

Complete Zinc oxide Off-gas Desulfurization Equipment

The complete zinc oxide off-gas desulfurization equipment is applied to remove sulfur dioxide in the off-gas generated from lead-zinc smelters. That is, zinc oxide is used as desulfurization agent to react with SO₂ in the off-gas to generate ZnSO₃, in such way the off-gas is desulfurized.

Specification & Series:Customizable to features and process flow of the process medium, transportation conditions and customer requirements.

Specification & Series:Customizable to features and process flow of the process medium, transportation conditions and customer requirements.

Application Fields:This equipment is applicable to the desulfurization of a variety of off-gas generated from the lead-zinc smelter, with the intermediate product of the smelter, zinc oxide soot being used as the desulfurization agent.

Application Fields:This equipment is applicable to the desulfurization of a variety of off-gas generated from the lead-zinc smelter, with the intermediate product of the smelter, zinc oxide soot being used as the desulfurization agent.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

High desulfurization efficiency. When the SO₂ concentration of inlet off-gas is about 6000mg/Nm³, second-stage absorption is adopted with the average desulfurization efficiency of more than 99%.

High desulfurization efficiency. When the SO₂ concentration of inlet off-gas is about 6000mg/Nm³, second-stage absorption is adopted with the average desulfurization efficiency of more than 99%.

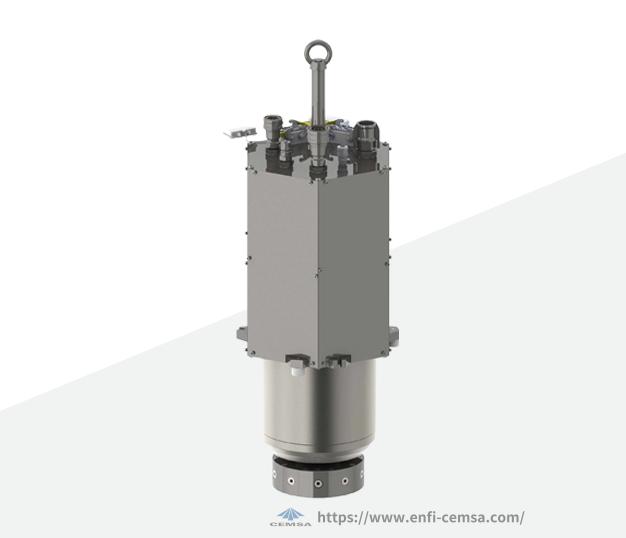

Adopting empty tower spray absorption equipment. The equipment is superior to dynamic wave from the aspect of reaction time and better than turbulent ball tower in terms of anti-blocking.

Adopting empty tower spray absorption equipment. The equipment is superior to dynamic wave from the aspect of reaction time and better than turbulent ball tower in terms of anti-blocking.

The equipment also has the function of comprehensive utilization of waste acid.

The equipment also has the function of comprehensive utilization of waste acid.

No secondary pollution. The by-products completely return to the smelting process to realize a seamless connection with the desulfurization process.

No secondary pollution. The by-products completely return to the smelting process to realize a seamless connection with the desulfurization process.

Safe operation. Solution is free of strong acid and alkali in the whole process; Except for the original off-gas, the temperature of other solids, liquids and gases shall not be higher than 60 ℃, without scald risk and high-pressure gas.

Safe operation. Solution is free of strong acid and alkali in the whole process; Except for the original off-gas, the temperature of other solids, liquids and gases shall not be higher than 60 ℃, without scald risk and high-pressure gas.

Working Principle

Zinc oxide desulfurization is such method by adding water in the materials containing zinc oxide powder to prepare slurry which contacts with the low-concentration SO₂ in the off-gas in the absorption equipment to remove SO₂ in the off-gas in the forms of zinc sulfite, zinc sulfate and zinc bisulfite. The zinc sulfite is oxidized to a soluble zinc sulfate solution by the air injected into the bottom of the absorption device.

The Application Achievements

Related Recommendations