HOMEPAGE > PRODUCTS > Solid waste treatment > Hazardous Waste High-Efficiency Combustion-Smelting Equipment Package

Product Brief

Hazardous Waste High-Efficiency Combustion-Smelting Equipment Package

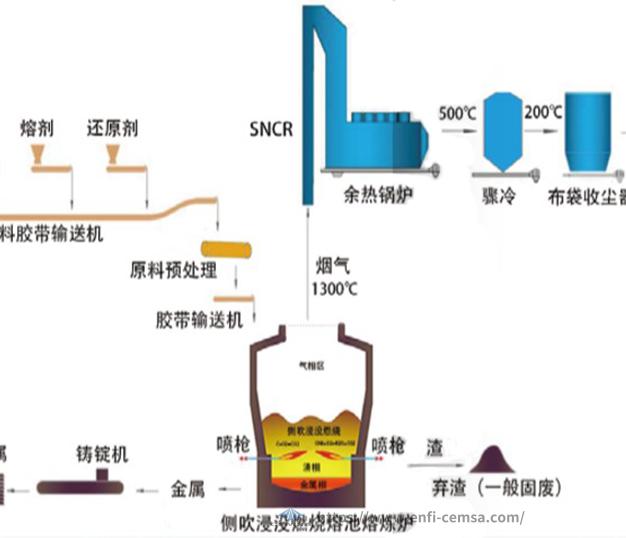

The hazardous waste high-efficiency combustion-smelting equipment package (Combustion-Smelting Process, CS for short), which is among the core expertise equipment of ENFI, actualizes the ultimate treatment of organic bearing hazardous waste by "combustion + smelting”, constituting a major breakthrough in existing incineration technology.

The equipment package solved the difficulties in the integrated incineration of multi-types of organic hazardous wastes. It has completely eliminated the necessity of landfilling secondary products/ashes resulted from the incineration of hazardous wastes for 100% harmless recycling and truly realized the safe reuse of all components of hazardous waste in full compliance with the state requirement of “zero-waste city”.

The package includes two parts: countercurrent rotary kiln and high temperature melting EF.

The equipment package solved the difficulties in the integrated incineration of multi-types of organic hazardous wastes. It has completely eliminated the necessity of landfilling secondary products/ashes resulted from the incineration of hazardous wastes for 100% harmless recycling and truly realized the safe reuse of all components of hazardous waste in full compliance with the state requirement of “zero-waste city”.

The package includes two parts: countercurrent rotary kiln and high temperature melting EF.

Specification & Series:30t/d, 50t/d, 70t/d, 100t/d, etc.

Specification & Series:30t/d, 50t/d, 70t/d, 100t/d, etc.

Processing Capacity:The hazardous waste treatment capacity of single production line is 30t/d-100t/d.

Processing Capacity:The hazardous waste treatment capacity of single production line is 30t/d-100t/d.

Application Fields:This set of equipment can be used in the fields of chemical pharmacy, non-ferrous metallurgy, urban minerals, etc. The equipment can be used for treating industrial wastes containing organic matter and heavy metals and medical wastes. The project location needs to have stable power resource and water source, and can be built in an industrial developed area.

Application Fields:This set of equipment can be used in the fields of chemical pharmacy, non-ferrous metallurgy, urban minerals, etc. The equipment can be used for treating industrial wastes containing organic matter and heavy metals and medical wastes. The project location needs to have stable power resource and water source, and can be built in an industrial developed area.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

Feed into the counter-current rotary kiln is in immediate contact with high-temperature flue gas and is rapidly dried and pyrolyzed to produce combustible gas that is burned in the secondary combustion chamber to save fuel.

Feed into the counter-current rotary kiln is in immediate contact with high-temperature flue gas and is rapidly dried and pyrolyzed to produce combustible gas that is burned in the secondary combustion chamber to save fuel.

Hazardous waste and hot flue gas flow in reverse directions, which maintain high thermal efficiency. It also reduces the erosion of hazardous waste moisture on refractory materials at the entrance of the rotary kiln, prolonging the life of the kiln. The shorter length of rotary kiln saves investment.

Hazardous waste and hot flue gas flow in reverse directions, which maintain high thermal efficiency. It also reduces the erosion of hazardous waste moisture on refractory materials at the entrance of the rotary kiln, prolonging the life of the kiln. The shorter length of rotary kiln saves investment.

An obvious gradient of oxygen concentration is formed along the axial direction, which is conducive to realize the working condition for "pyrolysis - combustion" of dried hazardous waste and eliminate the generation of dioxins at the source.

An obvious gradient of oxygen concentration is formed along the axial direction, which is conducive to realize the working condition for "pyrolysis - combustion" of dried hazardous waste and eliminate the generation of dioxins at the source.

Melting glass slag is formed in high-temperature melting furnace to realize reduced slag quantity and resource utilization.

Melting glass slag is formed in high-temperature melting furnace to realize reduced slag quantity and resource utilization.

Valuable metal can be recovered, maximizing profit.

Valuable metal can be recovered, maximizing profit.

Working Principle

Working principles of hazardous waste countercurrent high-efficiency incineration- high temperature melting equipment system are as follows:

①Hazardous waste is heated, dried, ignited and pyrolyzed into inflammable gas under anoxic condition. The macromolecular organic matters are first pyrolyzed or vaporized into small molecular organic matters to reduce the precursors of dioxin, which can reduce the emission of dioxin from the source. Part of the inflammable gas is introduced into the secondary combustion chamber to save fuel;

②The inflammable gas is forced to be mixed with air and ignited in the secondary combustion chamber, and oxidized at high temperature under sufficient air supply. The high temperature pyrolysis and incineration can completely decompose toxic and harmful substances;

③Multifunctional hock cooling devices are provided in the off-gas ultra-clean emission system to avoid the resynthesis of dioxin. And dust collection and deacidification devices are provided to make sure of the ultra-clean emission of the off-gas;

The ash slag is melted and tempered in the high temperature melting furnace, and the heavy metals are formed into stable minerals with SiO42-mesh lattices to prepare building materials for comprehensive utilization.

①Hazardous waste is heated, dried, ignited and pyrolyzed into inflammable gas under anoxic condition. The macromolecular organic matters are first pyrolyzed or vaporized into small molecular organic matters to reduce the precursors of dioxin, which can reduce the emission of dioxin from the source. Part of the inflammable gas is introduced into the secondary combustion chamber to save fuel;

②The inflammable gas is forced to be mixed with air and ignited in the secondary combustion chamber, and oxidized at high temperature under sufficient air supply. The high temperature pyrolysis and incineration can completely decompose toxic and harmful substances;

③Multifunctional hock cooling devices are provided in the off-gas ultra-clean emission system to avoid the resynthesis of dioxin. And dust collection and deacidification devices are provided to make sure of the ultra-clean emission of the off-gas;

The ash slag is melted and tempered in the high temperature melting furnace, and the heavy metals are formed into stable minerals with SiO42-mesh lattices to prepare building materials for comprehensive utilization.

Technical Parameters

| S/N | Item | Unit | Indicator | Remarks |

|---|---|---|---|---|

| 1 | Throughput | T | 30/50/70/100 | |

| 2 | Furnace (rotary kiln) temperature | ℃ | >950 | |

| 3 | Post-combustion chamber | ℃ | >1100 | |

| 4 | Residence time of the flue gas Longer than 24 seconds | s | ≥2 | |

| 5 | Efficiency | % | ≥99.9 | |

| 6 | Removal rate | % | ≥99.99 | |

| 8 | Loss of ignition | % | <5 | |

| 9 | Oxygen content in flue gas of secondary combustor | % | 44357 | |

| 10 | Off-gas temperature at WHB inlet | ℃ | 550 | |

| 11 | Off-gas retention time of quench tower | s | <1 | |

| 12 | Outlet flue gas temperature | ℃ | <200 | |

| 13 | Annual rated operating time: | h | ≥7200 | 300 days per year on average capacity |

| 14 | Load range | % | 70-120 | |

| 15 | Harmless resource utilization of secondary ash and slag | % | 100 | |

| 16 | Fuel consumption is reduced compared with similar downstream combustion technologies | % | 50 | |

| S/N | Pollutant | Unit | Standard | Remarks |

| 1 | Off-gas temperature | Ringelman I | ||

| 2 | Dust | mg/Nm³ | 30 | Measured average |

| 3 | 1) Carbon monoxide (CO) | mg/Nm³ | 80 | Measured average |

| 4 | (1) SO2 | mg/Nm³ | 200 | Half-hour average |

| 5 | d. HF | mg/Nm³ | 2 | Half-hour average |

| 6 | Hydrogen Chloride as HCl | mg/Nm³ | 50 | Half-hour average |

| 7 | (5) Nitric acid and nitrogen oxide (NOX) | mg/Nm³ | 400 | Half-hour average |

| 8 | Hg and its compounds | mg/Nm³ | 0.05 | Measured average |

| 9 | Cadmium and its compounds (in TL + CD) | mg/Nm³ | 0.05 | Measured average |

| 10 | As and its compounds | mg/Nm³ | 0.05 | Measured average |

| 11 | Pb and its compounds | mg/Nm³ | 0.5 | Measured average |

| 12 | Chromium, tin, antimony, copper, manganese, nickel and their compounds (in terms of CR + Sn + Sb + Cu + Mn + Ni) | mg/Nm³ | 2 | Measured average |

| 13 | Dioxin-like substances (TEQ) | TEQng/m³ | 0.1 | Measured average |

The Application Achievements

Related Recommendations