Product Brief

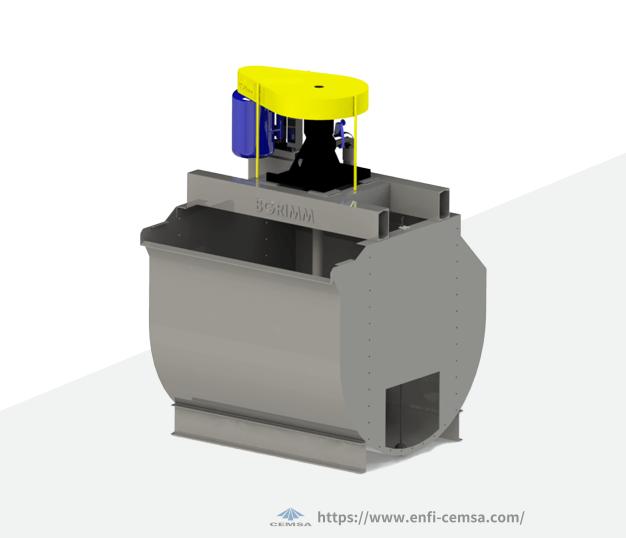

KYF Forced Air Flotation Cell

KYF Flotation machine is an advanced aerated agitating flotation machine that can be used for roughing, scavenging and cleaning operations. To accommodate for different on-site process conditions, mineral properties and equipment sizes, the cell can be designed as circular or U-shaped vessel. This system is also good for recovering coarse-to-fine grained minerals. The pre-mineralization effect in the impeller cavity can effectively improve the fine-grained particles recovery effect, and the flotation machine technology with a higher froth transfer zone can help strengthen the recovery of coarse particles. Additionally, the system produces good gas dispersion effect.

Specification & Series:0.03m³~680m³

Specification & Series:0.03m³~680m³

Processing Capacity:KYF-10 3-10m3/min

KYF-20 5-20m3/min

KYF-30 7-30m3/min

KYF-40 8-38m3/min

KYF-50 10-40m3/min

Processing Capacity:KYF-10 3-10m3/min

KYF-20 5-20m3/min

KYF-30 7-30m3/min

KYF-40 8-38m3/min

KYF-50 10-40m3/min

Application Fields:Roughing, scavenging, cleaning and high-altitude operation for recovering metallic and non-metallic minerals

Application Fields:Roughing, scavenging, cleaning and high-altitude operation for recovering metallic and non-metallic minerals

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

Lower energy consumption.

Lower energy consumption.

Better air dispersion.

Better air dispersion.

The impeller acts as a centrifugal pump, keeping the solids in suspension in the entire cell volume.

The impeller acts as a centrifugal pump, keeping the solids in suspension in the entire cell volume.

Low wear and maintenance costs.

Low wear and maintenance costs.

Start-up under load.

Start-up under load.

Lower regent consumption.

Lower regent consumption.

Simple construction and easy maintenance.

Simple construction and easy maintenance.

U tank construction, short-circuiting is well prevented.

U tank construction, short-circuiting is well prevented.

Advanced pump level control system and aeration control system.

Advanced pump level control system and aeration control system.

The suction flotation cells which volume is less than 70m3 can be provided, ensure all banks flotation cells on the same level without forth pump.

The suction flotation cells which volume is less than 70m3 can be provided, ensure all banks flotation cells on the same level without forth pump.

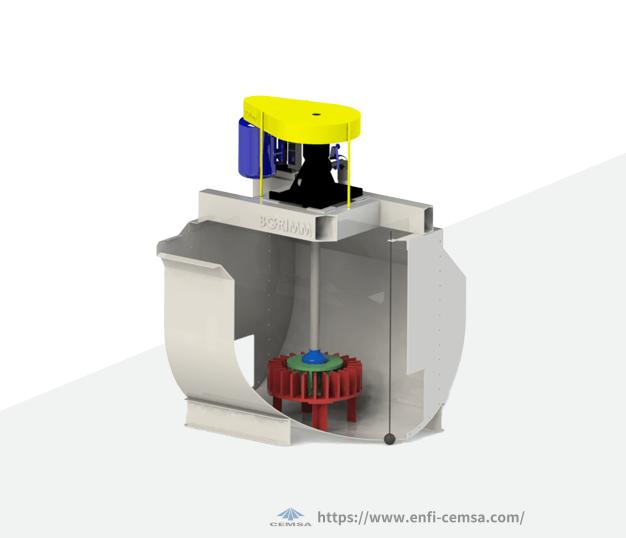

Working Principle

1.The rotation of the impeller creates a pressure difference, and the slurry in the cell is sucked into the space between the impeller blades

2.The low-pressure air blown in by fan enters between impeller blades via the hollow spindle

3.Air distributor installed inside the impeller cavity

4.Air pre-cutting via porous structure

5.Enabling pre-mineralization of air bubbles with particles in the impeller cavity and uniform distribution of air bubbles in the cell

6.Air bubbles discharged via upper part of the impeller

7.Turning into radial flow from rotational flow as a result of flow stabilization and guiding by the stator

8.Mineralized bubbles ascends to form the froth layer

9.Scraped into froth launder by scraper

Technical Parameters

| 规格 TYPE | 有效容积 Effective capacity | 安装功率 Rated power | 最小进口风压 Minimum inlet air pressure | 充气量 Aeration rate |

|---|---|---|---|---|

| U型槽体 | m3 | kW | kPa | m3/m2min |

| KYF-1 | 1 | 4 | >11 | 0.1~1.4 |

| KYF-2 | 2 | 5.5 | >12 | 0.1~2.4 |

| KYF-3 | 3 | 7.5 | >14 | 0.1~3.6 |

| KYF-4 | 4 | 11 | >15 | 0.2~4.5 |

| KYF-6 | 6 | 18.5 | >17 | 0.2~5.9 |

| KYF-8 | 8 | 22 | >19 | 0.2~6.8 |

| KYF-10 | 10 | 30 | >20 | 0.3~8.1 |

| KYF-16 | 16 | 37 | >23 | 0.4~11.0 |

| KYF-20 | 20 | 45 | >25 | 0.5~12.6 |

| KYF-24 | 24 | 55 | >27 | 0.5~13.5 |

| KYF-30 | 30 | 55 | >31 | 0.6~17.2 |

| KYF-40 | 40 | 75 | >32 | 0.7~20.2 |

| KYF-50 | 50 | 90 | >33 | 1.0~27.1 |

| 规格 TYPE | 有效容积 Effective volume | 安装功率 Rated power | 最小进口风压 Minimum inlet air pressure | 充气量 Aeration rate |

| 圆形槽体 | m3 | kW | kPa | m3/m2min |

| KYF-5 | 5 | 11 | >15 | 0.2~4.8 |

| KYF-10 | 10 | 22 | >20 | 0.3~8.6 |

| KYF-16 | 16 | 30 | >23 | 0.5~12.7 |

| KYF-24 | 24 | 37 | >27 | 0.5~12.7 |

| KYF-30 | 30 | 45 | >31 | 0.6~15.9 |

| KYF-40 | 40 | 75 | >33 | 0.7~18.9 |

| KYF-50 | 50 | 75 | >33 | 0.8~23.3 |

| KYF-70 | 70 | 90 | >41 | 1.0~21.6 |

| KYF-100 | 100 | 132 | >46 | 1.4~41.0 |

| KYF-130 | 130 | 160 | >50 | 1.7~49.7 |

| KYF-160 | 160 | 160 | >52 | 1.9~57.7 |

| KYF-200 | 200 | 220 | >56 | 2.2~66.2 |

| KYF-320 | 320 | 280 | >64 | 2.6~79.2 |

| KYF-680 | 680 | 500 | >45 | 4.7~142.5 |

The Application Achievements

Related Recommendations