HOMEPAGE > PRODUCTS > Bottom blowing process > Large High-efficiency Self-regulating Disc Pelletizer

Product Brief

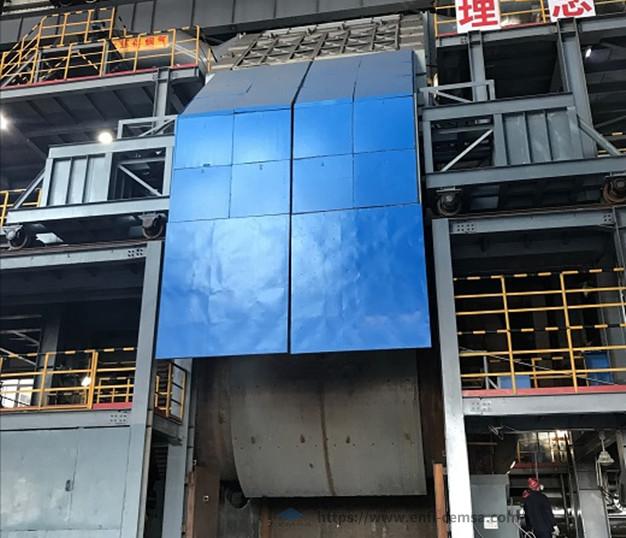

Large High-efficiency Self-regulating Disc Pelletizer

As a product independently developed by ENFI, large high-efficiency self-regulating disc pelletizer can make fine-grained powder into pellets with a particle size up to the requirements of smelting process, so as to improve smelting efficiency. The equipment is characterized by advanced structure, reliable performance, good pelletizing effect, low energy consumption, wear resistance, stable operation and easy maintenance.

Specification & Series:Series of product specification: disc diameters are 3.8m, 5.5m and 6m respectively

Specification & Series:Series of product specification: disc diameters are 3.8m, 5.5m and 6m respectively

Processing Capacity:6-65t/h

Processing Capacity:6-65t/h

Application Fields:It is applicable to materials such as Cu concentrate, Pb concentrate, dust, briquettes, pulverized coal and limestone.

Application Fields:It is applicable to materials such as Cu concentrate, Pb concentrate, dust, briquettes, pulverized coal and limestone.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

Advanced structure and reliable performance. The originally designed triangular rack facilitates the adjustment of disc’s dip angle and lowers the equipment’s center of gravity, reducing the total weight of equipment and improving operation stability of equipment. The large-size disc with crossed roller bearing is adopted, electric rotary scraper is used to clean up sticky materials, light and convenient device for disc dip angle adjustment is employed, and the inner surface of disc is lined with expanded metal mesh to make its operation stable and reliable.

Advanced structure and reliable performance. The originally designed triangular rack facilitates the adjustment of disc’s dip angle and lowers the equipment’s center of gravity, reducing the total weight of equipment and improving operation stability of equipment. The large-size disc with crossed roller bearing is adopted, electric rotary scraper is used to clean up sticky materials, light and convenient device for disc dip angle adjustment is employed, and the inner surface of disc is lined with expanded metal mesh to make its operation stable and reliable.

Good pelletizing effect. Multiple sprayers are used to add water in the form of mist, and the water volume, spraying angle and point can be adjusted to facilitate pelletizing. The operation parameters of equipment can be adjusted in real time so as to meed the demands of pelletizing a wide variety of materials.

Good pelletizing effect. Multiple sprayers are used to add water in the form of mist, and the water volume, spraying angle and point can be adjusted to facilitate pelletizing. The operation parameters of equipment can be adjusted in real time so as to meed the demands of pelletizing a wide variety of materials.

Low energy consumption. The transmission device has advanced technology and short transmission chains, and it can operate under a relatively low power, ensuring low electricity consumption, energy conservation and environmental protection.

Low energy consumption. The transmission device has advanced technology and short transmission chains, and it can operate under a relatively low power, ensuring low electricity consumption, energy conservation and environmental protection.

Small maintenance workload. The equipment is highly reliable with advanced lubrication technology (or equipped with centralized lubrication technology), and wear parts have a long service life and are easy to replace, greatly reducing the maintenance workload.

Small maintenance workload. The equipment is highly reliable with advanced lubrication technology (or equipped with centralized lubrication technology), and wear parts have a long service life and are easy to replace, greatly reducing the maintenance workload.

Durability and a long service life. High polymer materials are adopted as the liner of the inner surface of disc, greatly alleviating abrasion to the disc surface and reducing bond between materials and electricity consumption during pelletizing.

Durability and a long service life. High polymer materials are adopted as the liner of the inner surface of disc, greatly alleviating abrasion to the disc surface and reducing bond between materials and electricity consumption during pelletizing.

Working Principle

The powder material rolls and rubs under the effort of gravity, centrifugal force and friction force in the inclined and rotating disc, and forms the mother ball under the condition of adding appropriate water. The fine-grained material rolls on the wet surface of the mother ball to make it get bigger and have a certain strength. The pellets with different particle sizes automatically run along different tracks in the disc, and the finished pellets meeting the requirements are discharged from the disc.

Technical Parameters

| Specification & Series | Disc diameter | Disc dip angle | Throughput | Main motor power | Scraper power |

|---|---|---|---|---|---|

| Φ3,800mm disc pelletizer | Φ3,800mm | 45°-55° | 6t/h | 37kW | 3*2.2kW |

| Φ5,500mm disc pelletizer | Φ5,500mm | 45°-56° | 30t/h | 75kW | 3*3kW |

| Φ6,000mm disc pelletizer | Φ6,000mm | 45°-57° | 60t/h | 90kW | 3*3kW |

The Application Achievements

Related Recommendations