Product Brief

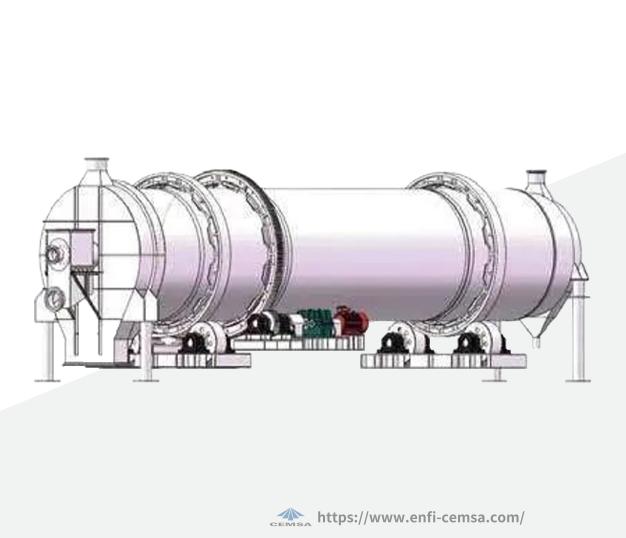

Large fluidized-bed roaster

In 1992, China ENFI designed and built the first 109m² fluidized-bed roasting system of the country and successfully put it into production at one stretch at Northwest Smelter. The 109m² fluidized-bed roaster is the key equipment for the zinc smelting process with a single-series capacity of 100kt/a and above. With constant improvement, ENFI has successively applied over 20 sets of roasters of such scale to zinc smelters owned by companies such as Zhuzhu Smelter Group, Bayannur Zijin, Yuguang Zinc Industry, NFC Zinc, Chihong ZINC & Germanium, Huludao Zinc Industry Co., Ltd

So far, over 90% of large zinc smelting companies in China have adopted the large fluidized-bed roaster designed by ENFI.

Specification & Series:Product specification (furnace bed area): 109m², 152m², 186m²

Specification & Series:Product specification (furnace bed area): 109m², 152m², 186m²

Application Fields:The fluidized-bed roaster is mainly applied to zinc concentrate roasting, as well as other roasting feed such as copper concentrate, gold concentrate, tin concentrate, nickel concentrate, laterite and pyrite.

Application Fields:The fluidized-bed roaster is mainly applied to zinc concentrate roasting, as well as other roasting feed such as copper concentrate, gold concentrate, tin concentrate, nickel concentrate, laterite and pyrite.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

High roasting intensity of up to 7~8t/㎡.d zinc concentrate;

High roasting intensity of up to 7~8t/㎡.d zinc concentrate;

Low sulfur residual rate in roasted products, with insoluble sulfur ≤0.4%;

Low sulfur residual rate in roasted products, with insoluble sulfur ≤0.4%;

High heat recovery, approx. 1t of steam produced from 1t of zinc sulfide concentrate;

High heat recovery, approx. 1t of steam produced from 1t of zinc sulfide concentrate;

High degree of automation, a small number of operators needed, and low production cost.

High degree of automation, a small number of operators needed, and low production cost.

Working Principle

Roasting is mainly to turn zinc sulfide into zinc oxide, (ZnS+O₂=ZnO+SO₂) from which the flue gas is sent to make acid after waste heat boilers and dust collection.

Technical Parameters

| Parameters of Roaster | 109 m² | 152 m² | 186 m² |

|---|---|---|---|

| Hearth area (m²) | 109 | 152 | 186 |

| Hearth diameter (m) | 11.8 | 13.9 | 16.4 |

| Expansion diameter (m) | 16.3 | 17.58 | 19.5 |

| Cone height (m) | 6.18 | 6.48 | 7 |

| Cone angle (m) | 20 | 16 | 16 |

| Hearth total height (m) | 22.4 | 25.9 | 26.44 |

| Hood (pcs) | 10882 | 15034 | |

| Treatment capacity (104t/a Zn) | 10~13 | 15~18 | 18~22 |

| Annual working time (d) | >340 | >340 | >340 |

| Specific capacity (t/ m²·d) | >7 | >7 | >7 |

The Application Achievements

Related Recommendations