Product Brief

New High-power Electric Furnace and Control System

New high-power electric furnace and control system is the core equipment of pyrometallurgical FeNi smelting technology with RKEF process developed by ENFI has filled the gaps in FeNi smelting in China, making the Chinese FeNi smelting industry at the forefront of the world. The 72,000kVA EF for FeNi smelting which is designed and supplied by ENFI is hailed as the FeNi smelting EF with the largest capacity independently designed in China for the present.

Application Fields:The EF is applicable to smelting of various metallic or non-metallic raw materials, including nickel, copper, industrial silicon, copper-cobalt alloy, FeNi, vanadium-titanium, phosphorus, etc.

Application Fields:The EF is applicable to smelting of various metallic or non-metallic raw materials, including nickel, copper, industrial silicon, copper-cobalt alloy, FeNi, vanadium-titanium, phosphorus, etc.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

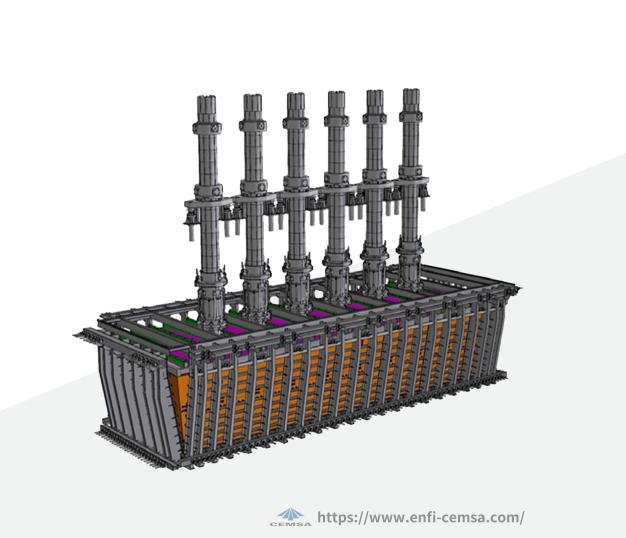

The EF is comprised of a furnace body of inverted trapezoidal structure, overall elastic framework and electrode assemblies, characterized by high-efficiency, energy saving and eco-friendliness.

The EF is comprised of a furnace body of inverted trapezoidal structure, overall elastic framework and electrode assemblies, characterized by high-efficiency, energy saving and eco-friendliness.

The EF boasts a capacity of up to 72MVA, a service life of over 10 years and a capability to generate FeNi products with a grade of 10%-37%.

The EF boasts a capacity of up to 72MVA, a service life of over 10 years and a capability to generate FeNi products with a grade of 10%-37%.

Meanwhile, an integrated and intelligent control system for EF is developed to accomplish efficient operation with low energy consumption.

Meanwhile, an integrated and intelligent control system for EF is developed to accomplish efficient operation with low energy consumption.

Technical Parameters

| Power | Usage | Qty | Slag line area | Startup year | Client |

|---|---|---|---|---|---|

| 33,000KVA | FeNi smelting EF | 2 | 134.4m2 | 2010 | Fu’an, Fujian |

| 72,000KVA | FeNi smelting EF | 2 | 288m2 | 2012 | Tagaung Taung, Myanmar |

| 36,000KVA | FeNi smelting EF | 2 | 196m2 | 2013 | Fangchenggang, Guangxi |

The Application Achievements

Related Recommendations