HOMEPAGE > PRODUCTS > Side blowing process > Super-large side-blowing converting (SSC) technical equipment and control system

Product Brief

Super-large side-blowing converting (SSC) technical equipment and control system

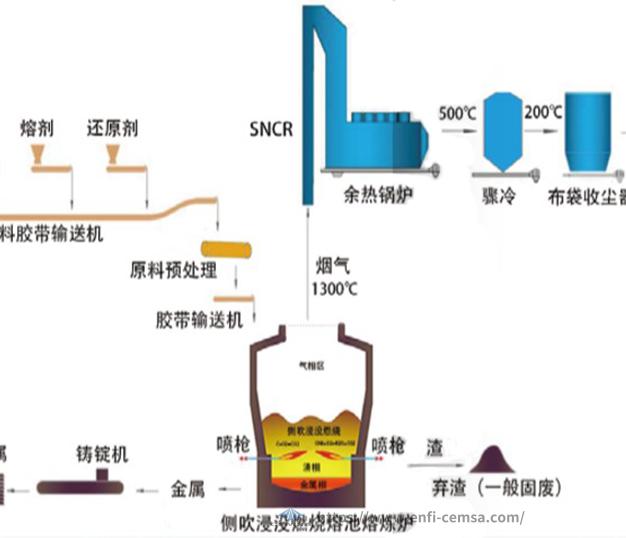

SSC furnace is one of the core equipment of Side-Submerged Combustion Smelting Process (SSC). SSC is an intensive smelting technology where the oxygen-enriched air or fuel is directly blown via the tuyere or lance that is submerged in the bath into the metal flux or slag, with the intensive stirring of blast, the feed with flux added is fast immersed into the flux where chemical reactions occur. Due to its high oxygen concentration, strong adaptability to fuel, reasonable furnace structure, and when compared with similar technology, SSC outstands and differentiates itself by of higher heat utilization rate, higher operation efficiency, being more safer, environmental friendly and energy saving among others.

Application Fields:It is mainly applied in direct reduction of molten lead-rich slag, large-scale industrial solid waste treatment and secondary lead field.

Application Fields:It is mainly applied in direct reduction of molten lead-rich slag, large-scale industrial solid waste treatment and secondary lead field.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

High adaptability.

High adaptability.

The SSC furnace is adapted to a variety of materials without self-heating characteristics, which means it has a low requirement on the feed moisture content; no strict pelletizing or brick pressing is required, the preparing of feed is sample; side-blowing lance is is adapted to a variety of fuels, including natural gas, generator gas, coke oven gas, pulverized coal, diesel oil, pyrolysis oil, used mineral oil, etc; Targeted settling zone is arranged. The recovery of valuable metals are high;

Targeted settling zone is arranged. The recovery of valuable metals are high;

High availability and low maintenance and repair burden

High availability and low maintenance and repair burden

The service life of bricks surrounding the oxygen lance is 1 year above.

The service life of refractory materials is 3 years above.

Annual average efficient availability is more than 300 days. Waste slag recycling

Waste slag recycling

The smelting slag is in a form of glassy state, which is of general solid waste that can be used as building materials, hence secondary pollution can be avoided.

The Application Achievements

Related Recommendations