Product Brief

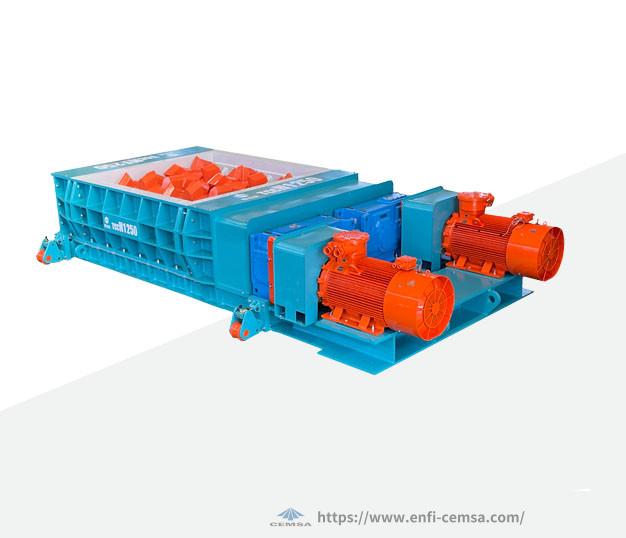

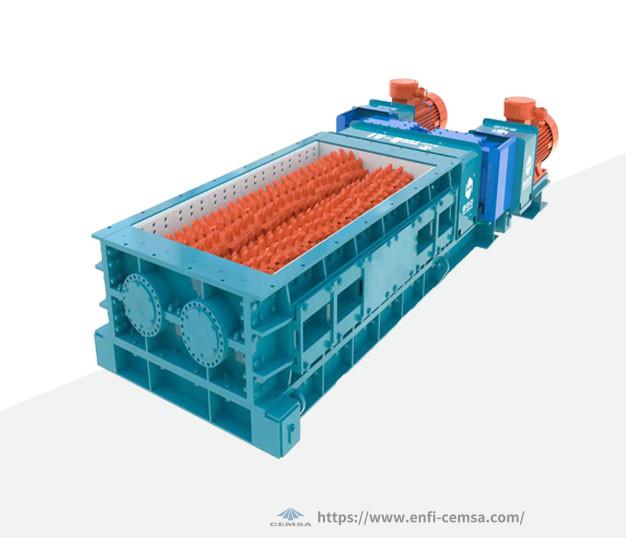

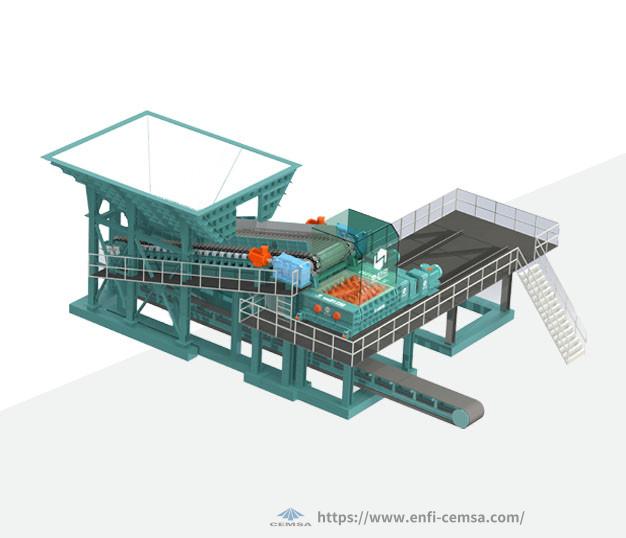

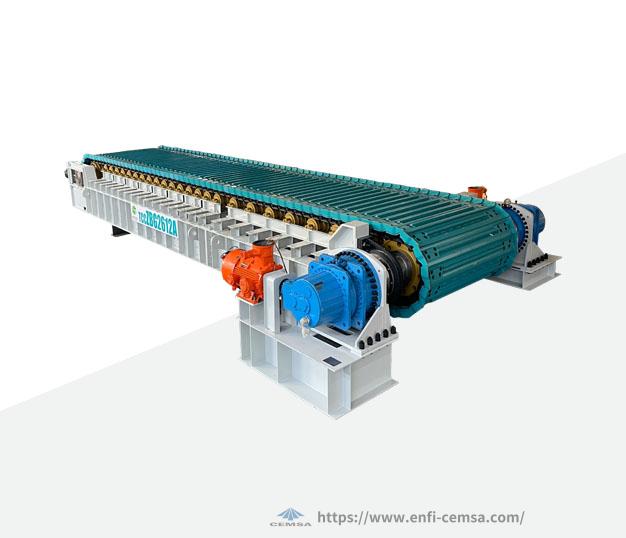

TCC sizing crusher

Tcc Crusher has been committed to the development of sizers since 1994, TCC Sizers are suitable for underground, surface, fixed and mobile crushing, and can be utilized in a wide variety of configurations to meet your production demands. Primary, secondary, tertiary and quaternary models can be combined for single or multiple stage crushing formats.

Specification & Series:TCC-H series heavy-duty sizer;

TCC-A series standard sizer;

TCC-F series economical sizer;

TCC-S series solid waste sizer;

TCC-B series mixed crusher

Specification & Series:TCC-H series heavy-duty sizer;

TCC-A series standard sizer;

TCC-F series economical sizer;

TCC-S series solid waste sizer;

TCC-B series mixed crusher

Processing Capacity:10,000TPH

Processing Capacity:10,000TPH

Application Fields:The sizers are successful in multiple applications and are often the preferred choice in iron ore,gold ore,coal and bauxite,limestone,nickel ore,lithium ore applications.

Application Fields:The sizers are successful in multiple applications and are often the preferred choice in iron ore,gold ore,coal and bauxite,limestone,nickel ore,lithium ore applications.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

The mineral is directly crushed, featuring a dual function of crushing and screening, with a maximum processing capacity of up to 10,000tph.

The mineral is directly crushed, featuring a dual function of crushing and screening, with a maximum processing capacity of up to 10,000tph.

With wide range of feed and product size applications, feeding size up to 1,500mm;

With wide range of feed and product size applications, feeding size up to 1,500mm;

Reasonable crushing ratio2-5, up to 6;

Reasonable crushing ratio2-5, up to 6;

Ore ranging from soft to hard, UCS up to 250MPa;

Ore ranging from soft to hard, UCS up to 250MPa;

.Insensitive wet and sticky feeds, with clearing tooth device.

.Insensitive wet and sticky feeds, with clearing tooth device.

Working Principle

The graded crushing technology, through the design of the crusher teeth shape,teeth arrangement and installation form, to achieve the feeder material pass directly or selected crushing, and only materials larger than the product size will be crushed, otherwise, materials will pass directly. For it can accurately control product size and with low over-crushing rate, it has dual functions of crushing and screening.

Technical Parameters

| 设备型号 | D | LR | 入料粒度 | 出料粒度 | 破碎强度 | 通过能力 | 处理能力 | 电机功率[kw] | 设备重量 |

|---|---|---|---|---|---|---|---|---|---|

| 设备型号 | 破碎辊直径. | 破碎辊长度. | (mm) | (mm) | (MPa) | [t/h] | [t/h] | 电机功率[kw] | [t] |

| TC6005 V/H18.5 | 600 | 500 | 200(100) | 50 | 160 | 60-90 | 30-50 | 2´18.5 | 6 |

| TC6010V/H22 | 600 | 1000 | 200(100) | 50 | 160 | 120-180 | 80-120 | 2´22 | 7.5 |

| TC6015V/H37 | 600 | 1500 | 200(100) | 50 | 160 | 150-280 | 100-200 | 2´37 | 9 |

| TC6020V/H45 | 600 | 2000 | 200(100) | 50 | 160 | 200-300 | 120-250 | 2´45 | 11 |

| TC6025V/H75 | 600 | 2500 | 200(100) | 50 | 160 | 350-600 | 250-400 | 2´75 | 16 |

| TC6030V/H110 | 600 | 3000 | 200(100) | 50 | 160 | 500-800 | 300-500 | 2´110 | 22 |

| TC6035V/H160 | 600 | 3500 | 200(100) | 50 | 160 | 700-1200 | 400-600 | 2´160 | 28 |

| TC6040V/H200 | 600 | 4000 | 200(100) | 50 | 160 | 900-1500 | 500-800 | 2´200 | 45 |

| TC7010V/H30 | 700 | 1000 | 300(150) | 50 | 160 | 120-180 | 80-130 | 2´30 | 8 |

| TC7015V/H55 | 700 | 1500 | 300(150) | 50 | 160 | 150-250 | 100-200 | 2´55 | 10 |

| TC7020V/H75 | 700 | 2000 | 300(150) | 50 | 160 | 200-300 | 120-250 | 2´75 | 15 |

| TC7025V/H90 | 700 | 2500 | 300(150) | 50 | 160 | 350-600 | 250-400 | 2´90 | 20 |

| TC7030V/H132 | 700 | 3000 | 300(150) | 50 | 160 | 500-800 | 300-500 | 2x132 | 28 |

| TC7035V/H160 | 700 | 3500 | 300(150) | 50 | 160 | 700-1200 | 400-600 | 2´160 | 35 |

| TC7040V/H200 | 700 | 4000 | 300(150) | 50 | 160 | 900-1500 | 500-800 | 2´200 | 48 |

| TC7050V/H250 | 700 | 5000 | 300(150) | 50 | 160 | 1200-2000 | 650-1000 | 2´250 | 64 |

| TC7060 V/H315 | 700 | 6000 | 300(150) | 50 | 160 | 1800-2400 | 800-1500 | 2´315 | 90 |

| TC8010V/H75(S132) | 800 | 1000 | 600 | 200 | 200 | 100-600 | 100-400 | 2´75(132) | 16 |

| TC8010V/H55 | 800 | 300 | 50 | 160 | 120-200 | 100-150 | 2´55 | 10 | |

| TC8015V/H90(S160) | 800 | 1500 | 600 | 200 | 200 | 500-1000 | 300-750 | 2´90(160) | 18 |

| TC8015V/H75 | 800 | 300 | 50 | 160 | 150-300 | 120-240 | 2´75 | 15 | |

| TC8020V/H110(S200) | 800 | 2000 | 600 | 200 | 200 | 800-2000 | 400-1000 | 2´110(200) | 24 |

| TC8020V/H75 | 800 | 300 | 50 | 160 | 200-400 | 150-300 | 2´75 | 20 | |

| TC8025V/H90(S250) | 800 | 2500 | 600 | 200 | 200 | 1500-2500 | 600-1200 | 2´132(250) | 30 |

| TC8025V/H90 | 800 | 300 | 50 | 160 | 350-600 | 200-450 | 2´90 | 24 | |

| TC8030V/H160(S315) | 800 | 3000 | 600 | 200 | 200 | 2000-4000 | 800-2500 | 2´160(315) | 35 |

| TC8030V/H110 | 800 | 300 | 50 | 160 | 500-800 | 400-650 | 2´110 | 28 | |

| TC8040V/H250(S450) | 800 | 4000 | 600 | 200 | 200 | 3000-6000 | 1800-4000 | 2´250(450) | 42 |

| TC8040V/H200 | 800 | 300 | 50 | 160 | 900-1500 | 500-900 | 2´200 | 32 | |

| TC10015V/H110(S200) | 1000 | 1500 | 500-900 | 150-300 | 250 | 500-1500 | 300-1200 | 2´110(200) | 20 |

| TC10020V/H132(S250) | 1000 | 2000 | 500-900 | 150-300 | 250 | 800-2500 | 500-1800 | 2´132(250) | 26 |

| TC10030V/H200(S355) | 1000 | 3000 | 500-900 | 150-300 | 250 | 1500-3000 | 800-2400 | 2´200(355) | 40 |

| TC10040V/H280(S560) | 1000 | 4000 | 500-900 | 150-300 | 250 | 2500-8000 | 1200-4000 | 2´280(560) | 60 |

| TC12520V/H200(S355) | 1250 | 2000 | 800-1200 | 200-400 | 300 | 1000-3000 | 800-2400 | 2´200(355) | 38 |

| TC125V30/H280(S500) | 1250 | 3000 | 800-1200 | 200-400 | 300 | 3000-8000 | 1800-5000 | 2´280(500) | 60 |

| TC15020V/H250(S500) | 1500 | 2000 | 1000-1500 | 300-500 | 300 | 1200-4000 | 600-2400 | 2´250(500) | 56 |

| TC15030V/H315(S600) | 1500 | 3000 | 1000-1500 | 300-500 | 300 | 3000-10000 | 1800-5000 | 2´315(600) | 89 |

| TC15040V/H400(S730) | 1500 | 4000 | 1000-1500 | 300-500 | 300 | 5000-15000 | 2400-7000 | 2´400(730) | 100 |

| TC20020V/H280(S500) | 2000 | 2000 | 1200-2000 | 400-500 | 300 | 1500-5000 | 800-3000 | 2´280(500) | 60 |

| TC20030V/H355(S730) | 2000 | 3000 | 1200-2000 | 400-500 | 300 | 3000-12000 | 1200-6000 | 2´355(710) | 90 |

| TC20040V/H450(S900) | 2000 | 4000 | 1200-2000 | 400-500 | 300 | 5000-18000 | 2400-9000 | 2x450(900) | 130 |

The Application Achievements

Related Recommendations