Product Brief

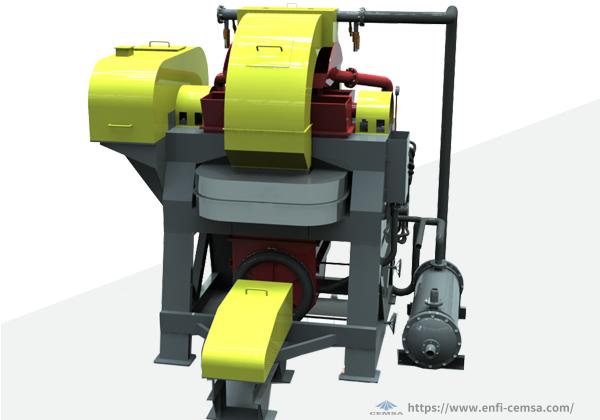

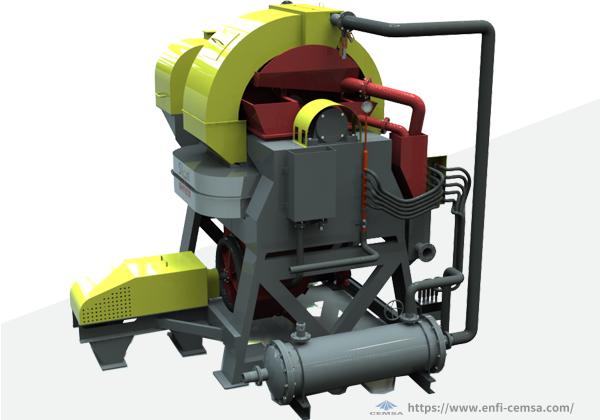

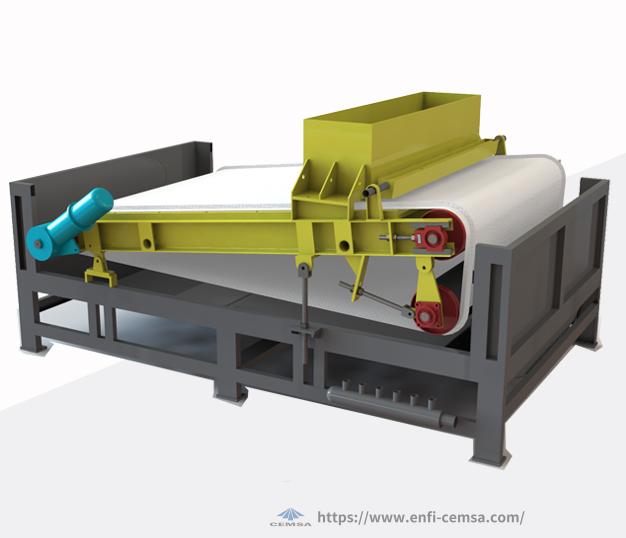

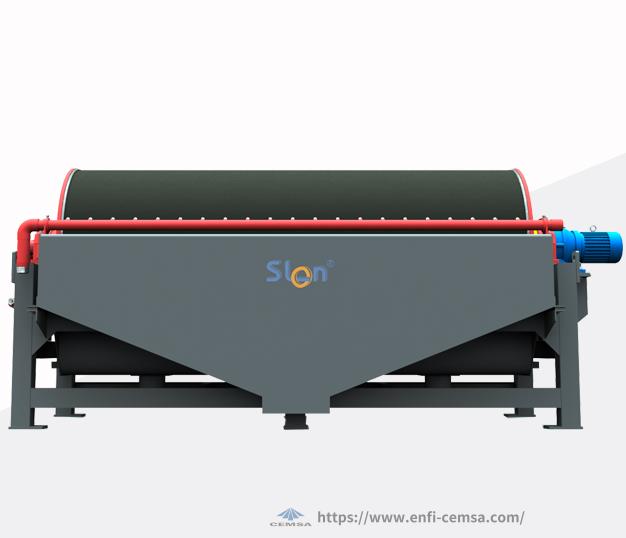

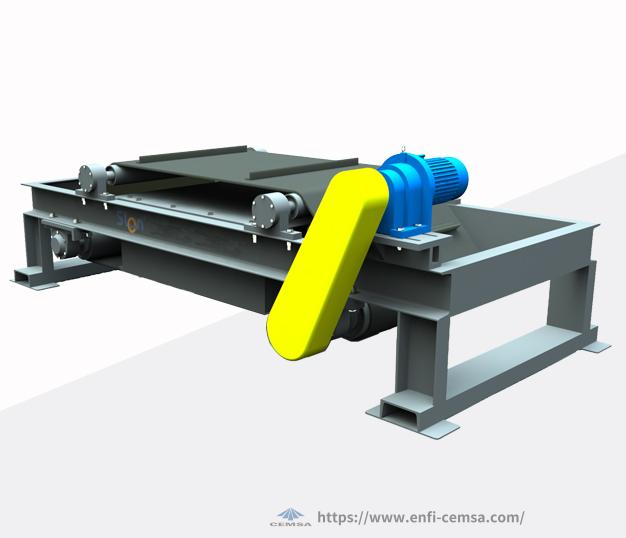

Wet High Intensity Magnetic Separator(WHIMS)

HGMS is an electromagnetic equipment invented by CEMSA, which adapts unique magnetic system structure and sorting device to achieve the separation of mags and non mags.

Specification & Series:SLon-5000

SLon-4000

SLon-3500

SLon-3000

SLon-2750

SLon-2500

SLon-2250

SLon-2000

SLon-1750

SLon-1500

SLon-1250

SLon-1000

SLon-750

SLon-500

Specification & Series:SLon-5000

SLon-4000

SLon-3500

SLon-3000

SLon-2750

SLon-2500

SLon-2250

SLon-2000

SLon-1750

SLon-1500

SLon-1250

SLon-1000

SLon-750

SLon-500

Processing Capacity:0.03~950t/h

Processing Capacity:0.03~950t/h

Application Fields:hematite, limonite, ilmenite, chromite, manganese ore

Application Fields:hematite, limonite, ilmenite, chromite, manganese ore

non-metallic minerals, such as feldspar, silica sand, kaolin and so on.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

Low voltage, high current and low current density.Internal water cooling and double circulation cooling mode stable magnetic field. Magnetic separation equipment operation rate is up to 98%;

Low voltage, high current and low current density.Internal water cooling and double circulation cooling mode stable magnetic field. Magnetic separation equipment operation rate is up to 98%;

Optimized magnetic system design, optimal arrangement and combination of magnetic matrix, background field intensity up to 1.8T. vertical rotation, reverse flushing achieve magnetic matrix is not easy to block;

Optimized magnetic system design, optimal arrangement and combination of magnetic matrix, background field intensity up to 1.8T. vertical rotation, reverse flushing achieve magnetic matrix is not easy to block;

Pulsation mechanism design could improve the separation efficiency;

Pulsation mechanism design could improve the separation efficiency;

Wide separation range: from 2μm to 6mm;

Wide separation range: from 2μm to 6mm;

Equipped with coil pipeline cleaning system, easy for coil daily maintenance. coil designed life is up to 10 years.

Equipped with coil pipeline cleaning system, easy for coil daily maintenance. coil designed life is up to 10 years.

17 series of products with more than 70 specifications and models, and capacity of a single unit is from 0.01 to 950 t/h.

17 series of products with more than 70 specifications and models, and capacity of a single unit is from 0.01 to 950 t/h.

Working Principle

Slurry is introduced through slots in the upper yoke to the matrix, which is housed inside the vertical ring. The magnetic particles are attracted to the matrix and then carried outside of the magnetic field where they are subsequently flushed to the magnetic concentrate trough. The non-mags pass through the matrix to the non-mags collection hoppers.

Technical Parameters

| Parameters(1.0~1.2T) | SLon-500 | SLon-750(Ⅰ) | SLon-750(Ⅱ) | SLon-1000 | SLon-1250 | SLon-1500 | SLon-1750 | SLon-2000 | SLon-2250 | SLon-2500 | SLon-3000 | SLon-3500 | SLon-4000 | SLon-5000 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ring diameter /mm | 500 | 750 | 750 | 1000 | 1250 | 1500 | 1750 | 2000 | 2250 | 2500 | 3000 | 3500 | 4000 | 5000 |

| Ring speed /(r/min) | 0.3~3 | 0.3~3 | 2.5~3 | 2.5~3.5 | 2.5~3.5 | 2.5~3.5 | 2.5~3.5 | 2.5~3.5 | 2.5~3.5 | 2.5~3.5 | 2.5~3.5 | 2.5~3.5 | 2.5~3.5 | 2.5~3.5 |

| Feed size /(mm),(-74μm%) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) |

| Feed density/% | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 |

| Slurry throughput /(m3/h) | 0.25~0.5 | 0.5~1.0 | 5~10 | 12.5~20 | 20~50 | 50~100 | 75~150 | 100~200 | 160~300 | 200~400 | 350~650 | 550~1000 | 750~1400 | 1200~2300 |

| Ore throughput /(t/h) | 0.015~0.063 | 0.03~0.125 | 1~2 | 2~4 | 5~9 | 10~15 | 15~25 | 25~40 | 35~60 | 50~80 | 75~125 | 125~200 | 170~280 | 300~480 |

| Background field /T | 1/1.1 | 1/1.1 | 1/1.1 | 1/1.2 | 1/1.1 | 1/1.1 | 1/1.1 | 1/1.1 | 1/1.1 | 1/1.1 | 1/1.1 | 1/1.1 | 1/1.1 | 1/1.1 |

| Rated current /A | 1200 | 1100 | 800 | 800 | 850 | 900 | 1100 | 1100 | 1150 | 1200 | 1400 | 1600 | 1700 | 1900 |

| Rated voltage /V | 11 | 16 | 15 | 22 | 29 | 34 | 35 | 39 | 49 | 52 | 51 | 56 | 60 | 77 |

| Rated power /kW | 13 | 17 | 12 | 18 | 25 | 31 | 39 | 43 | 56 | 62 | 72 | 90 | 102 | 146 |

| Ring motor /kW | 0.18 | 0.55 | 0.75 | 1.1 | 1.5 | 3 | 4 | 5.5 | 7.5 | 11 | 18.5 | 30 | 37 | 55 |

| Water pressure /MPa | 0.1~0.2 | 0.1~0.2 | 0.1~0.2 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 |

| Flushing water consumption/(m3/h) | 0.75~1.5 | 0.75~1.5 | 5~8 | 8~14 | 20~36 | 40~60 | 60~100 | 80~120 | 120~160 | 160~220 | 240~400 | 400~600 | 560~800 | 950~1300 |

| Cooling water consumption /(m3/h) | 0.75~1.5 | 0.75~1.5 | 1~2 | 2~2.5 | 2~2.5 | 2~2.5 | 3~4 | 3~4 | 4~5 | 4~5 | 6~7 | 7~8 | 7~8 | 8~9 |

| Max part weight /t | 0.3 | 0.6 | 1 | 2.3 | 4 | 5 | 11 | 14 | 17 | 16 | 21 | 28 | 38 | 52 |

| Dimensions (L*W*H) /mm | 1030×1400×1350 | 1630×1400×1700 | 1220×1800×1750 | 1560×2100×2300 | 1940×2400×2700 | 2030×2900×3200 | 2490×3400×3800 | 2780×3460×4200 | 2900×3700×4500 | 3230×4350×5200 | 3880×5150×6300 | 4440×5400×7300 | 5020×6850×8300 | 6060×8000×10100 |

The Application Achievements

Related Recommendations