Product Brief

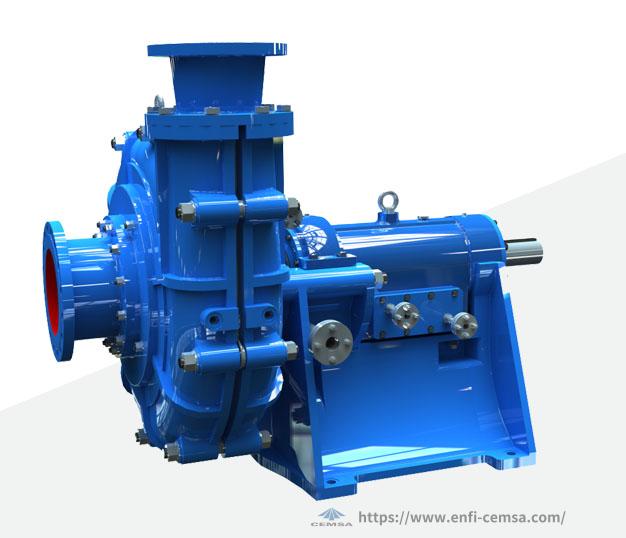

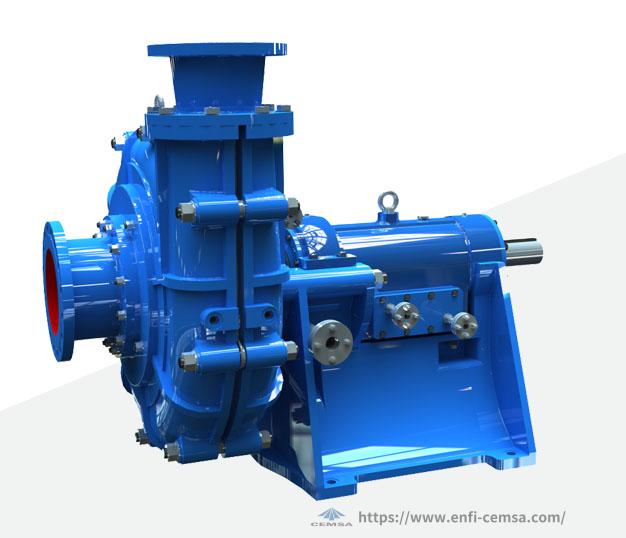

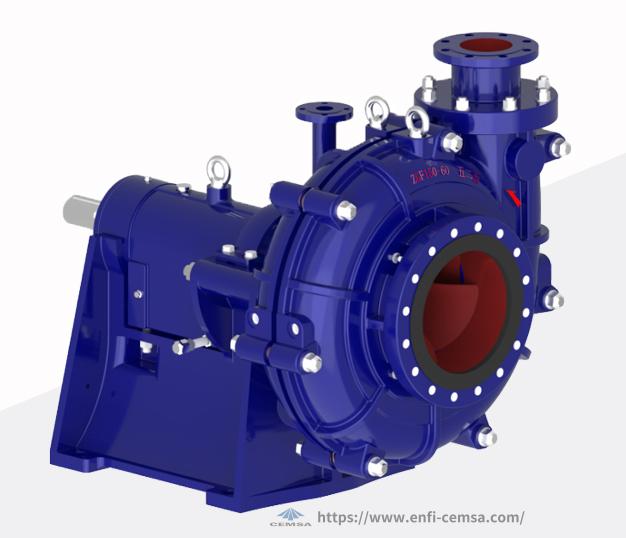

ZD/G Series Slurry Pump

ZD/G slurry pump is applied in fields of mine, metallurgical, power, coal, chemical and building materials, to meet requirements of transporting corrosion or erosion slurry solid practically containing, i.e.: coal cinder or coal-slurry in thermal power plant, slurry transport in metallurgy and concentrating mill, and coal slurry and dense medium transported in coal preparation plant.

Processing Capacity:Maxium mass density of slurry is 45% mortar and 60% ole pulp.

Processing Capacity:Maxium mass density of slurry is 45% mortar and 60% ole pulp.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

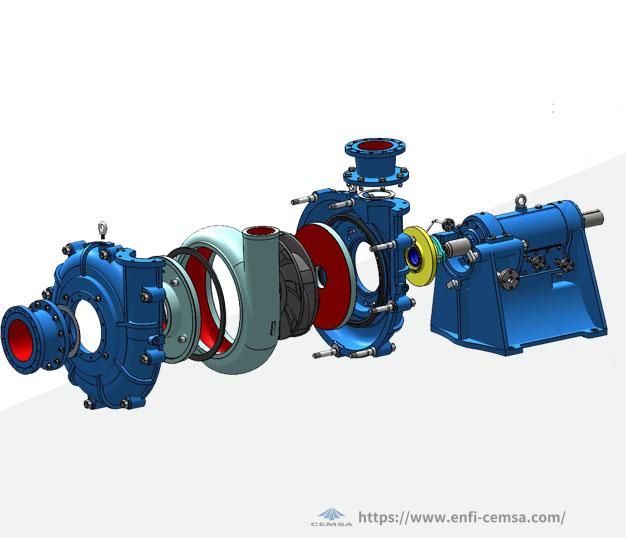

The pump is bolt jointed with pedestal. Pump outlet may be adjusted to connect in 8 positions at the inteval of 45° according to operation conditions.,and it is well designed for multistage connection.

The pump is bolt jointed with pedestal. Pump outlet may be adjusted to connect in 8 positions at the inteval of 45° according to operation conditions.,and it is well designed for multistage connection.

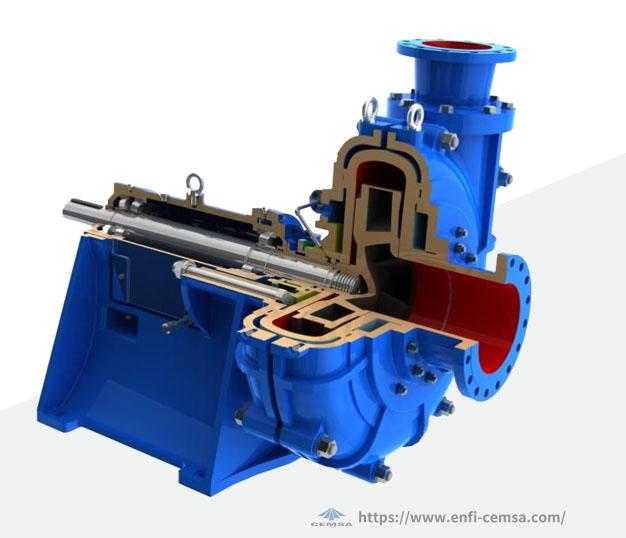

There is an adjusting bolt in the pedestal, which can be twisted to adjust clearance between impeller and front liner and be driven along bearing house axial moving, to make pump operating at the highest efficiency point.

There is an adjusting bolt in the pedestal, which can be twisted to adjust clearance between impeller and front liner and be driven along bearing house axial moving, to make pump operating at the highest efficiency point.

Flow parts will remain good interchangeability.

Flow parts will remain good interchangeability.

There is a temperature measuring device in bearing house, which beficial to data acquisitiion of DCS control system.

There is a temperature measuring device in bearing house, which beficial to data acquisitiion of DCS control system.

Technical Parameters

| Model | Maximum power allowed | Flow | Lift | Speed | Maximum efficiency | Cavitation allowance | Maximum granularity | Pump head weight |

|---|---|---|---|---|---|---|---|---|

| (m3/h) | (m) | (r/min) | (%) | (m) | (mm) | (kg) | ||

| ★40ZD-170 | 7.5 | 44674 | 9.0-44.5 | 1400-2900 | 52.4 | 2.5 | 11 | 240 |

| ★40ZG-190 | 11 | 8-34.9 | 12.8-57.1 | 1400-2900 | 58.8 | 1.3 | 11 | 405 |

| 40ZD-190 | 11 | 8-34.9 | 12.8-57.1 | 1400-2900 | 58.8 | 1.3 | 11 | 405 |

| 50ZD-330 | 18.5 | 12-54 | 7.7-42.5 | 700-1480 | 41.4 | 2.9 | 13 | 695 |

| 50ZG-460 | 55 | 23-94 | 17.9-85.8 | 700-1480 | 44.7 | 1.4 | 13 | 765 |

| 50ZD-460 | 55 | 23-94 | 17.9-85.8 | 700-1480 | 44.7 | 1.4 | 13 | 765 |

| 50ZG-500 | 90 | 27-111 | 22.3-110.7 | 700-1480 | 45.1 | 3 | 13 | 950 |

| 50ZD-500 | 90 | 27-111 | 22.3-110.7 | 700-1480 | 45.1 | 3 | 13 | 950 |

| 65ZD-300 | 15 | 23-80 | 7.4-35.8 | 700-1460 | 63.5 | 2 | 19 | 820 |

| 80ZD-360 | 45 | 46-190 | 9.6-51.5 | 700-1480 | 68.2 | 2.5 | 24 | 630 |

| 80ZG-420 | 75 | 61-204 | 14.4-70.6 | 700-1480 | 67.8 | 2.5 | 24 | 830 |

| 80ZD-420 | 75 | 61-204 | 14.4-70.6 | 700-1480 | 67.8 | 2.5 | 24 | 830 |

| 80ZG-520 | 160 | 51-242 | 22.1-109.8 | 700-1480 | 56.3 | 2.1 | 21 | 1025 |

| 80ZD-520 | 160 | 51-242 | 22.1-109.8 | 700-1480 | 56.3 | 2.1 | 21 | 1025 |

| 100ZD-360 | 55 | 61-245 | 9.7-48.6 | 700-1480 | 72.6 | 2 | 32 | 685 |

| 100ZG-420 | 90 | 66-275 | 14.7-71.0 | 700-1480 | 71 | 2.5 | 35 | 713 |

| 100ZD-420 | 90 | 66-275 | 14.7-71.0 | 700-1480 | 71 | 2.5 | 35 | 713 |

| 100ZG-500 | 160 | 85-360 | 20.5-101.6 | 700-1480 | 71.3 | 2.5 | 34 | 1065 |

| 100ZD-500 | 160 | 85-360 | 20.5-101.6 | 700-1480 | 71.3 | 2.5 | 34 | 1065 |

| 150ZG-500 | 75 | 115-460 | 9.5-43.1 | 490-980 | 78 | 2.5 | 48 | 1240 |

| 150ZD-500 | 75 | 115-460 | 9.5-43.1 | 490-980 | 78 | 2.5 | 48 | 1240 |

| 100ZG-570 | 185 | 130-270 | 26-115 | 700-1480 | 72 | 2.5 | 48 | 2000 |

| 100ZD-570 | 185 | 130-270 | 26-115 | 700-1480 | 72 | 2.5 | 48 | 2000 |

| 150ZG-600 | 160 | 135-550 | 14.7-64.5 | 490-980 | 77.5 | 2.5 | 48 | 2030 |

| 150ZD-600 | 160 | 135-550 | 14.7-64.5 | 490-980 | 77.5 | 2.5 | 48 | 2030 |

| 150ZG-650 | 200 | 150-600 | 17.4-78.5 | 490-980 | 72 | 2.5 | 48 | 2100 |

| 150ZD-650 | 200 | 150-600 | 17.4-78.5 | 490-980 | 72 | 2.5 | 48 | 2100 |

| 150ZG-700 | 185 | 93-400 | 20.0-91.2 | 490-980 | 62.3 | 2 | 37 | 1985 |

| 150ZD-700 | 185 | 93-400 | 20.0-91.2 | 490-980 | 62.3 | 2 | 37 | 1985 |

| 200ZG-600 | 200 | 218-870 | 13.9-64.0 | 490-980 | 82.7 | 2.5 | 62 | 2115 |

| 200ZD-600 | 200 | 218-870 | 13.9-64.0 | 490-980 | 82.7 | 2.5 | 62 | 2115 |

| 200ZG-650 | 250 | 235-950 | 16.4-72.0 | 490-980 | 80 | 2.5 | 62 | 2240 |

| 200ZD-650 | 250 | 235-950 | 16.4-72.0 | 490-980 | 80 | 2.5 | 62 | 2240 |

| 200ZG-700 | 315 | 205-976 | 19.4-86.4 | 490-980 | 75.6 | 2.8 | 56 | 2360 |

| 200ZD-700 | 315 | 205-976 | 19.4-86.4 | 490-980 | 75.6 | 2.8 | 56 | 2360 |

| 200ZG-750 | 355 | 225-900 | 22.8-103.0 | 490-980 | 74.5 | 3 | 56 | 2940 |

| 200ZD-750 | 355 | 225-900 | 22.8-103.0 | 490-980 | 74.5 | 3 | 56 | 2940 |

| 200ZG-850 | 560 | 221-907 | 32.0-133.7 | 490-980 | 70.5 | 2.8 | 54 | 3868 |

| 200ZD-850 | 560 | 221-907 | 32.0-133.7 | 490-980 | 70.5 | 2.8 | 54 | 3868 |

| 250ZG-650 | 315 | 299-1249 | 15.4-69.0 | 490-980 | 77.5 | 3 | 72 | 3105 |

| 250ZD-650 | 315 | 299-1249 | 15.4-69.0 | 490-980 | 77.5 | 3 | 72 | 3105 |

| 250ZG-750 | 560 | 300-1480 | 20.8-98.4 | 490-980 | 76 | 3 | 72 | 3240 |

| 250ZD-750 | 560 | 300-1480 | 20.8-98.4 | 490-980 | 76 | 3 | 72 | 3240 |

| 250ZG-850 | 800 | 376-1504 | 30.1-129.8 | 490-980 | 75.6 | 3.5 | 76 | 3870 |

| 250ZD-850 | 800 | 376-1504 | 30.1-129.8 | 490-980 | 75.6 | 3.5 | 76 | 3870 |

| 250ZG-960 | 560 | 595-1466 | 55.2-93.7 | 590-730 | 77.8 | 3.5 | 76 | 4625 |

| 250ZD-960 | 560 | 595-1466 | 55.2-93.7 | 590-730 | 77.8 | 3.5 | 76 | 4625 |

| 300ZD-600 | 250 | 395-1568 | 9.7-46.0 | 490-980 | 81.3 | 3.5 | 96 | 3025 |

| 300ZG-700 | 630 | 635-2333 | 16.0-76.8 | 490-980 | 80.4 | 3.9 | 92 | 3275 |

| 300ZD-700 | 630 | 635-2333 | 16.0-76.8 | 490-980 | 80.4 | 3.9 | 92 | 3275 |

| 300ZD-900 | 560 | 505-1844 | 21.2-80.0 | 400-730 | 81.5 | 3.8 | 85 | 4490 |

| 300ZG-1000 | 450 | 464-1826 | 15.3-65.2 | 300-590 | 80.8 | 3 | 88 | 5015 |

| 300ZD-1000 | 450 | 464-1826 | 15.3-65.2 | 300-590 | 80.8 | 3 | 88 | 5015 |

The Application Achievements

Related Recommendations